our mill story...

flying the flag for British manufacturing, the mill has been in continuous operation since at least 1841 and is still weaving today, employing over 40 local people

Our family story

The Griffiths family has been weaving here for over one hundred years. Henry Griffiths bought Melin Tregwynt in 1912 for £760 and then moved there with his young wife Esther.

Their two sons were Benjamin and Howard who left school at 14 to work with his father in the mill. Eluned, his wife, was only 18 when she married Howard and came to live at Tregwynt.

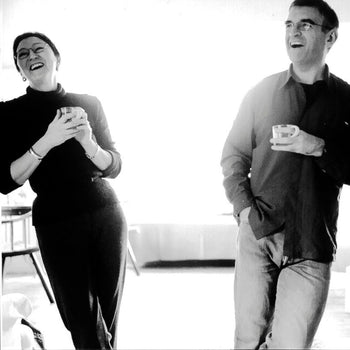

Howard’s son Eifion and his wife Amanda ran the Mill from 1986 up until 2022 when, they set up an Employee Owned Trust. They recognised that the skills and knowledge of all the staff is what keeps the tradition of Welsh weaving alive at Melin Tregwynt, The Trust keeps control of the company safely in the hands of the people who have been a major part of building its success

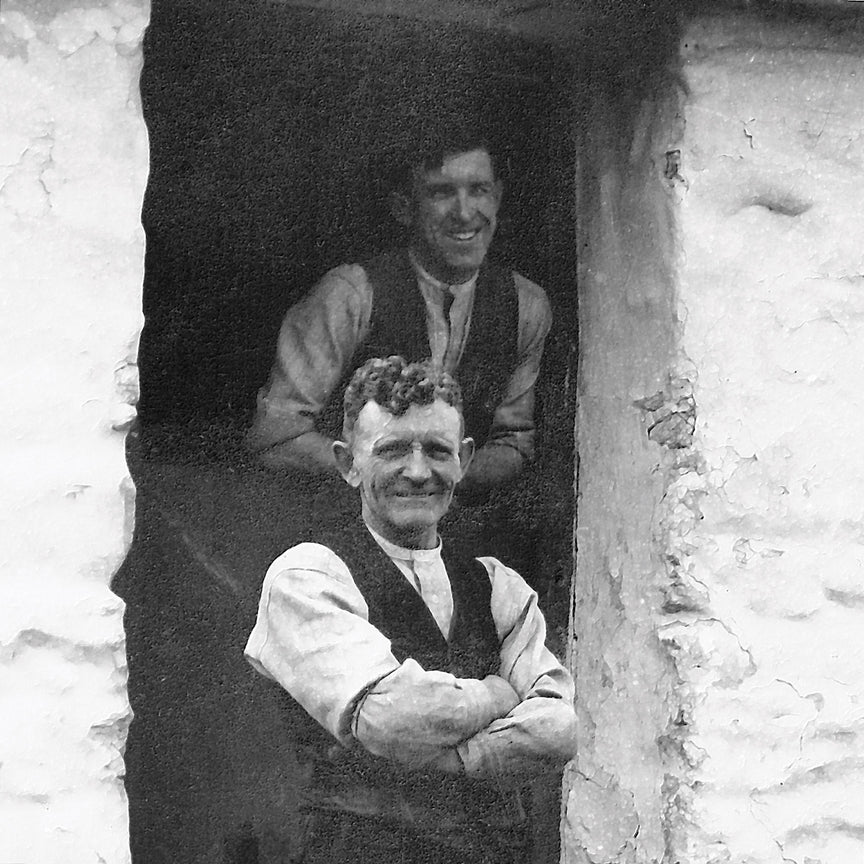

This photograph was originally taken for the magazine Country Life back in the late 40s.

the mill

In 1912 Henry Griffiths bought the mill for £750 and moved from Efailwen with his new wife Esther.

The Mill dates from the 18th century. It was originally part of the nearby Tregwynt estate. At that time the Harris family of Tregwynt Mansion owned all the surrounding land, stretching from just above Fishguard to beyond Mathry.

Originally a corn mill, records show that it later became a fulling mill (also known as a pandy mill). Water from the local stream was used to drive hammers and beat the woollen cloth to clean and soften the fabric. In those days it was known as Dyffryn (Valley) Mill.

They renamed it Tregwynt Mill after the original estate.

in the mill

This photo taken in the 1940’s shows Henry Griffiths operating the spinning mule, whilst behind him, his son Howard weaves tweed on a flying shuttle loom.

The carding engine with its huge rollers and the leather belts which drove all the machinery can be seen in the background.

The leather belts were directly connected to the water wheel, which is unusual in that it's located inside the building.

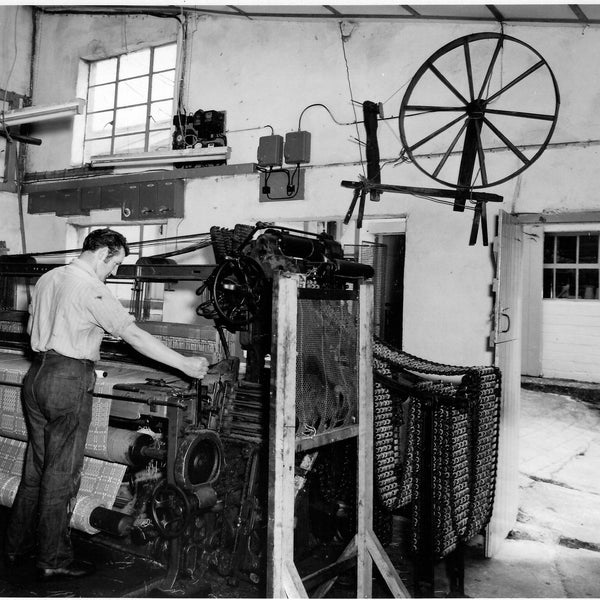

Howard warping

My father Howard setting up the warp before weaving.

Yarn skeins drying

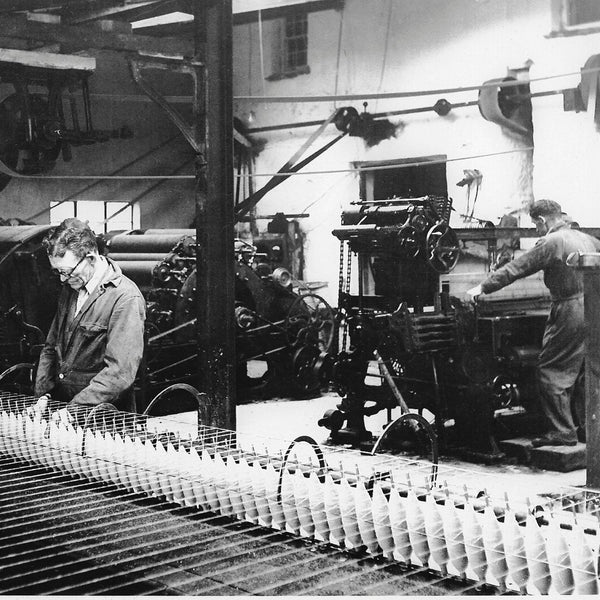

Glyn weaving

Glyn Devonald weaving one of the old Hattersley shuttle looms that were used in the mill until the late 70s. The shuttles flying back and forth made them very noisy and the weave patterns were created by linked metal cogs in a long chain, a very early form of mechanically driven binary computer.

Glyn who started work with us straight from school in the 1950s became mill manager in the 1960s

On the wall above you can see a traditional spinning wheel. It's still there today

Dai Williams

Dai Williams started work at the mill when he left school and became our mill manager in the late 1990s.

mending in the 90s

Howard with visitors

Howard Griffiths proudly displays the Melin Tregwynt St David’s Cross double cloth pattern. This design was woven on traditional flying shuttle looms over a 20 year period from 1960 onwards.

building the shop

The first shop - set up in the parlour of the house - proved very popular, so a seperate shop was built in the late 50s.

Today visitors will find a warm welcome 7 days a week, with staff who know our products inside and out, and are always happy to help you make your choice / help you decide

On weekdays you can listen to the clacking of the looms and watch our signature Welsh fabrics bring woven

Eluned in the millshop

Regular visitors to Melin Tregwynt will remember Eluned Griffiths behind the counter in the millshop. She worked here for over 50 years until her death in 2004.

Our Shop is anything but "run of the mill". We have a large stock of our very own blankets, throws and cushions, along with other great gifts plus food and drink from Wales

Today visitors will find a warm welcome, 7 days a week, with staff who know our products inside and out, and are always happy to help you make your choice / help you decide

On weekdays you can listen to the clacking of the looms and watch our signature Welsh fabrics bring woven

mill team in the 90s

the mill today

see how it's done...

the team

We still weave our cloth in the old whitewashed mill that my grandfather bought in 1912. If he came back to visit us today, he would still recognise the work being done, and the traditional skills of our weavers.

Its the skills and knowledge of our staff that have kept the tradition of Welsh weaving alive here at Melin Tregwynt.

When things are made in a certain way, traditional skills can be preserved, sustained and hopefully flourish and grow, supporting the industry and the people who make it.

Everyone here at the mill has their own story and we thought you'd like to get to know our team a little better.

design

Melin Tregwynt specialise in doublecloth and most of our fabrics have strong graphic designs with a retro, mid-century modern quality.

In addition to our stock ranges we have worked with many ompanies who have commissioned exclusive ranges of fabrics, throws and blankets.

We prepare CAD drawings, followed by handloom samples for approval, before a full run.

Lead times will depend on yarns, number of colours, designs chosen etc.

loading the creel

To weave, you first need to create a warp. This consists of a number of threads lying next to each other that run the whole length of the cloth.

Cones are set on the warping stand in a specific order of colours for the pattern of the cloth being warped.

warping

The ends of these cones are wound onto the warping wheel in sections of approx 200 threads each, to create the total width of the warp, (between 1600 and 3000 ends).

Each turn of the warping wheel creates about 4 to 5 metres of warp. At the end of a set number of turns, the bell rings to tell the warper to move on to the next section of 200 threads.

beaming off

Once the full warp has been created, it is wound off of the warping wheel onto a beam. The beam is then fixed on the back of the loom.

threading in

Each doublecloth design requires a minimum of 16 shafts. Widths 150/200/230 are possible. Each

shaft will require heddles (for yarn to pass through) of up to 2500 per warp depending on loom width, plus a reed to control the warp threads.

These heddles will all have to be re-threaded for each new design. This is normally done off the loom. To put new threaded shafts back on to the loom (and take out previous set of shafts) is about a day’s work

tying in the warp

If the loom is already set up with the desired ‘thread-up’, the new warp is tied on by hand to the old warp, using a ‘weaver’s knot’.

The ends must be tied together in the correct order and under tension, for the design of the cloth to be woven correctly.

Once the warp is set up on the loom, the cloth can then be woven (by sending weft threads across and through the warp). It is the combination of colour and structure that creates the varying designs of cloth.

Lifting the shafts to create the design

The shafts lift up and down in a particular sequence to create the desired structure. These are controlled by a punch-card chain which tells which shafts to lift and drop.

There is a corresponding pattern chain that controls the weft, so that each ‘pick’ or weft thread is sent across the cloth in the correct colour order.

weaving

Once the warp is set up on the loom, the cloth can then be woven (by sending weft threads across and through the warp).

The weft is carried straight off the cone, through an accumulator by the left-hand rapier. This meets the right-hand rapier which catches the weft and takes it across the remaining width of the cloth.

As the rapiers meet in the middle of the cloth, the weaving process is quicker and more efficient than weaving with flying shuttles. In fact, they move so fast it can be difficult to see them.

after weaving

The woollen cloth is wound onto a beam at the front of the loom. This is cut out in 30-50 metre lengths so that the cloth can be mended and finished.

quality control

Cloth is checked both sides for any knots or imperfections, and all faults are fixed/made as perfect as possible before finishing.

Cloth is folded, rolled and packed before being sent for finishing (washed, brushed, pressed etc) at our finishers in Scotland.

cutting and sewing the blankets, throws and cushions

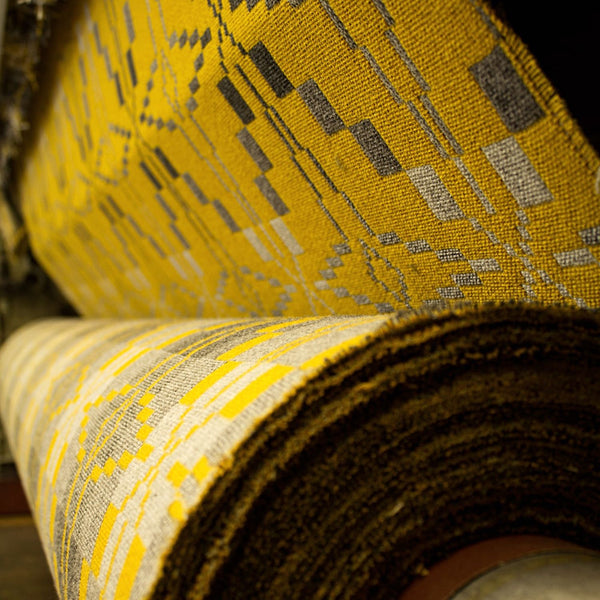

Once woven and finished we store our cloth on 30m long rolls, every throw, cushion and blanket is cut by hand on our specially built 2.5m square table.

Then our lovely sewing ladies sew every hem, seam, zip and label, checking that each item is perfect before it starts its journey to its new owner's home.

sewing smaller gifts

They also design, cut and make many small gifts in our fabrics

Jemima

You might recognise her friendly face from your visits to our café, or you’ll have been lucky enough to try one of her delicious coffees ☕️

Read more about Jemima and her two years working at the mill, here...

Paula

Paula's Melin Tregwynt journey story is very special as she is the third generation of her family to work for the bsuiness

Read more about her Melin Tregwynt journey here...

Holly

Holly works in the mill so you may have seen her friendly face around the site. One of our newer recruits she loves being a part of our amazing mill team, who are responsible for creating the beautiful textiles that we're known for.

Projects

Here are some examples of projects that we've collaborated on......

We're in the British Museum

A number of keen eyed supporters have spotted our fabrics on display in the Luxury and power: Persia to Greece exhibition which which runs from 4th May to 13th August 2023 at the British Museum

Largest Picnic Blanket in the World